- PRODUCTS

- >

- Semiconductor

- >

- Process Endpoint

- >

- Lightwind Wet Etch Endpoint Aep 2

Lightwind Wet Etch Endpoint Aep 2

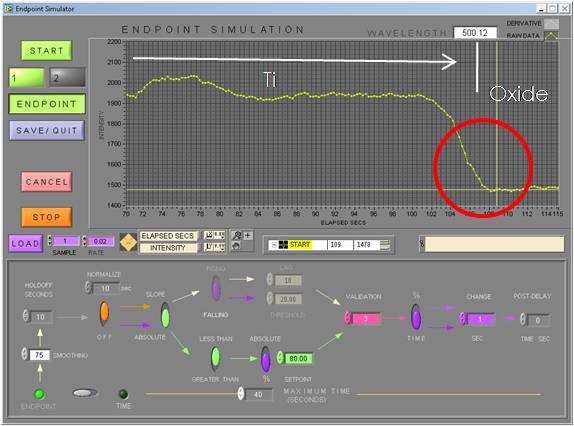

The Lightwind Aep 2 is an add-on endpoint system for wet processing. Utilizing optical reflectance spectroscopy, automated endpoint detection is now an option for many wet processing applications.

The Aep 2 is specifically designed to improve wet etch process control, while offering a measurement that adjusts to concentration changes in the bath. With time resolution of 1 second for endpoint, normal process variation and undercut are reduced and become more reproducible. Etch for many different films can be controlled by endpoint (such as Ti/oxide, Cu/Ti) .

Benefits of endpoint control

Improved Process Control

- 1 second resolution on measured wafer

- endpoint is based on wafer clearing, so it automatically adjusts

to changes in bath concentrations and temperature

- undercut associated with overetch is reduced

- endpoint allows more tolerance to batch chemistry variations

Cost savings

- automated endpoint minimizes process time associated with

fixed time processes, allowing higher throughput

- increased throughput, or simply reduced process time reduces

chemical costs and disposal costs

- reduction in number of test wafers required

Non Invasive

- endpoint hardware can be mounted outside the bath or process

enclosure in most cases

System Specification

Sensor Head Typically very small, configured to be tool specific

Consists of a light source and light detector

Light source Vis -NIR Optimized for films of interest

Lifetime Projected 10,000 hours or 1/ year

Spectrometer Vis / NIR Multichannel multiple

active wavelengths Resolution ~ 2 microns

Sample rate: variable depends on light but can be

as little as 10 milliseconds

Software Lightwind endpoint and data logging software

includes endpoint simulator, strip chart recording

data logging for selected channels or full spectra.

Output for ethernet/factory link.