Process Endpoint

|

Process Endpoint:

is an indicator that a change in a chemical process has occurred. may initiate a change in the tool state, such as a transition to a different process step (stoichiometry) is the result of a change in intensity of a wavelength or wavelengths. The change in intensity loosely correlates to a chemical concentration change in a plasma process. for industrial applications the better the processed signal to noise the more robust the endpoint. the endpoint call may be derived from a single wavelength or a combination of wavelengths. |

One of the most commonly used realtime measurements in semiconductor manufacturing is automatic endpoint. It is more frequently seen on plasma systems which naturally emit light. It is relatively easy to monitor the process chemistry (changes in wavelength intensity) as well as to determine when critical changes occur. The most important practical event monitored is the process change from one film to another. i.e. when a film layer is removed to expose an underlying film. This transition is a critical control point for minimizing process overetch (which has the potential to affect the critical dimensions of the devices). Most plasma endpoint systems rely on light emission in the uv to visible range of the spectra, but practically, endpoint may only rely on a few selected wavelengths. Numerical processing of the wavelengths transform them into signals that are more robust ( less susceptible to process "noise"). The process signal are continually compared to predetermined criteria to "stop" or advance the process.

The infrared region of the spectrum is another candidate area for process endpoint, however infrared endpoint is typically associated with its own dedicated IR light source and implemented in the exhaust line of the process chamber. This technique can be susceptible to build up of material on the detector window. This is also true of "thru the window endpoint systems. Lightwind offers a variety of endpoint solutions ranging from an exhaust unit that operates using its own remote plasma source, a "window based" endpoint system that relies on the light emission of the active process, and a wet etch endpoint system. The L3 self generates a plasma that is designed for continuous operation in the pump foreline. Since N2 is typically present a self cleaning affect is created that in many cases means maintenance is not required more than once a year. The S2 endpoint system is designed to monitor the process plasma through a chamber window. There are different spectrometer choices available which allow for "application" specific solutions.. i.e. solutions with enhanced sensitivity of critical wavelengths. The Aep2 is an endpoint system for wet etch processes: endpoint is determined by changes in the reflectivity of the film being etched. |

Downstream Endpoint for Vacuum Systems |

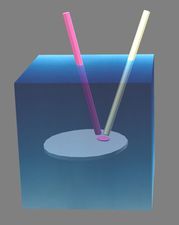

On Chamber Endpoint for Plasma Systems |

Endpoint for Wet Etch Systems |

|

Copyright © 2024

|