Process Monitoring and Control for Semiconductor Processes

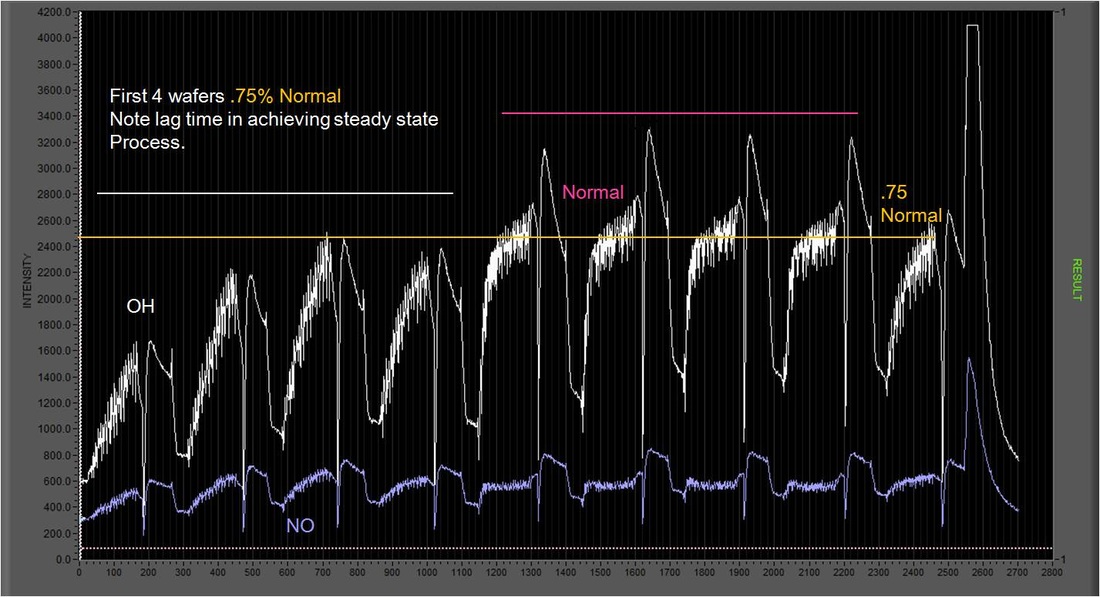

CVD Process Control And EndpointCVD processes are critical and so are chamber cleans. Overcleaning a reactor shortens the life of a chamber, undercleaning can cause premature flaking and particulates/defects. Many CVD systems do not have process monitoring or endpoint capability.

|

ALDALD precursors are very expensive and cannot be monitored as effectively as standard process gases. Flow failure causes device failure, and using higher gas flows for a safety margin is very costly. Using the L3 precursor flows can be optimized with significant cost saving.

|

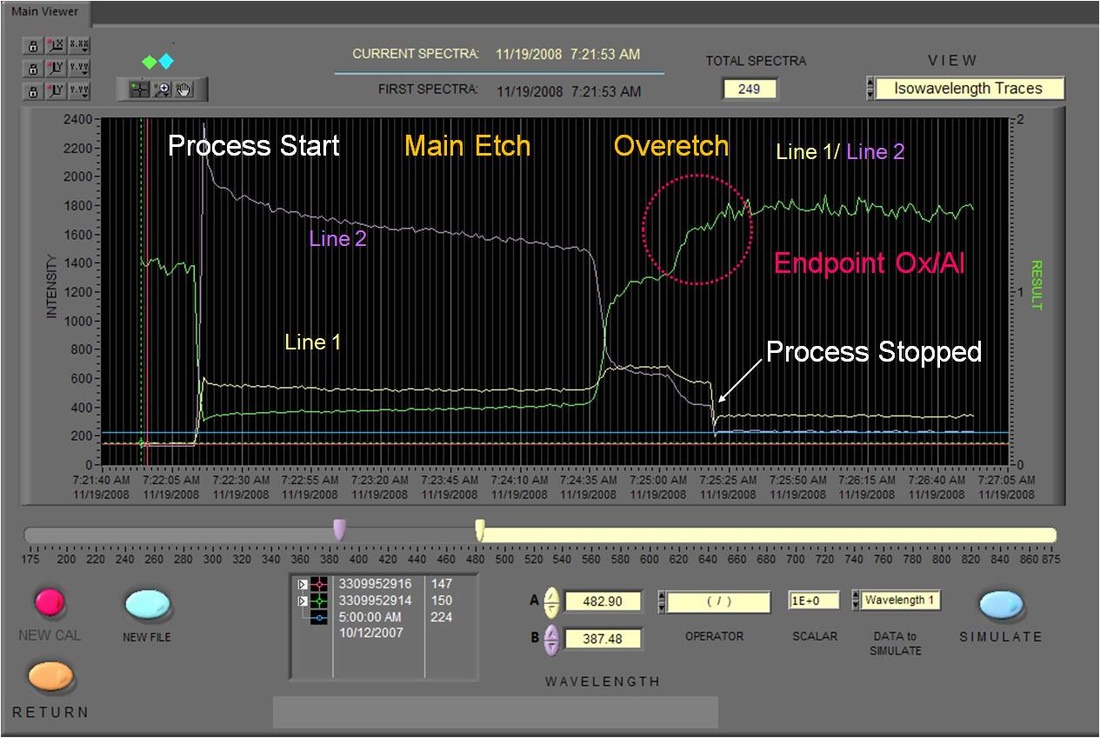

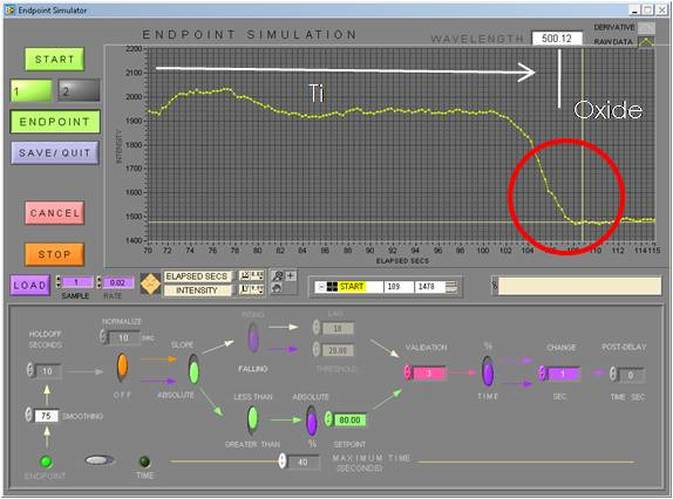

Plasma Etch EndpointAn important step in manufacturing is plasma etch. Accurate control of endpoint is critical for critical dimensions. Both the L and Series can provide process endpoint for very small geometries. In some cases such as contact etch an application specific spectrometer might be appropriate.

|

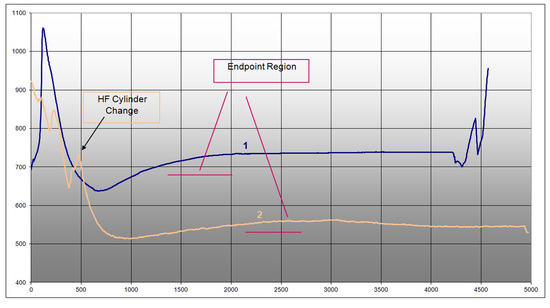

Wet Etch EndpointWet etch is a significant part of the process flown in semiconductor manufacturing. However, process control relies on timed etch whose accuracy depends on careful control of batch chemistry. Being able to monitor the etch rate real time using the Aep 2 can have provide significant cost savings as well as better process control.

|

|

Copyright © 2024

|